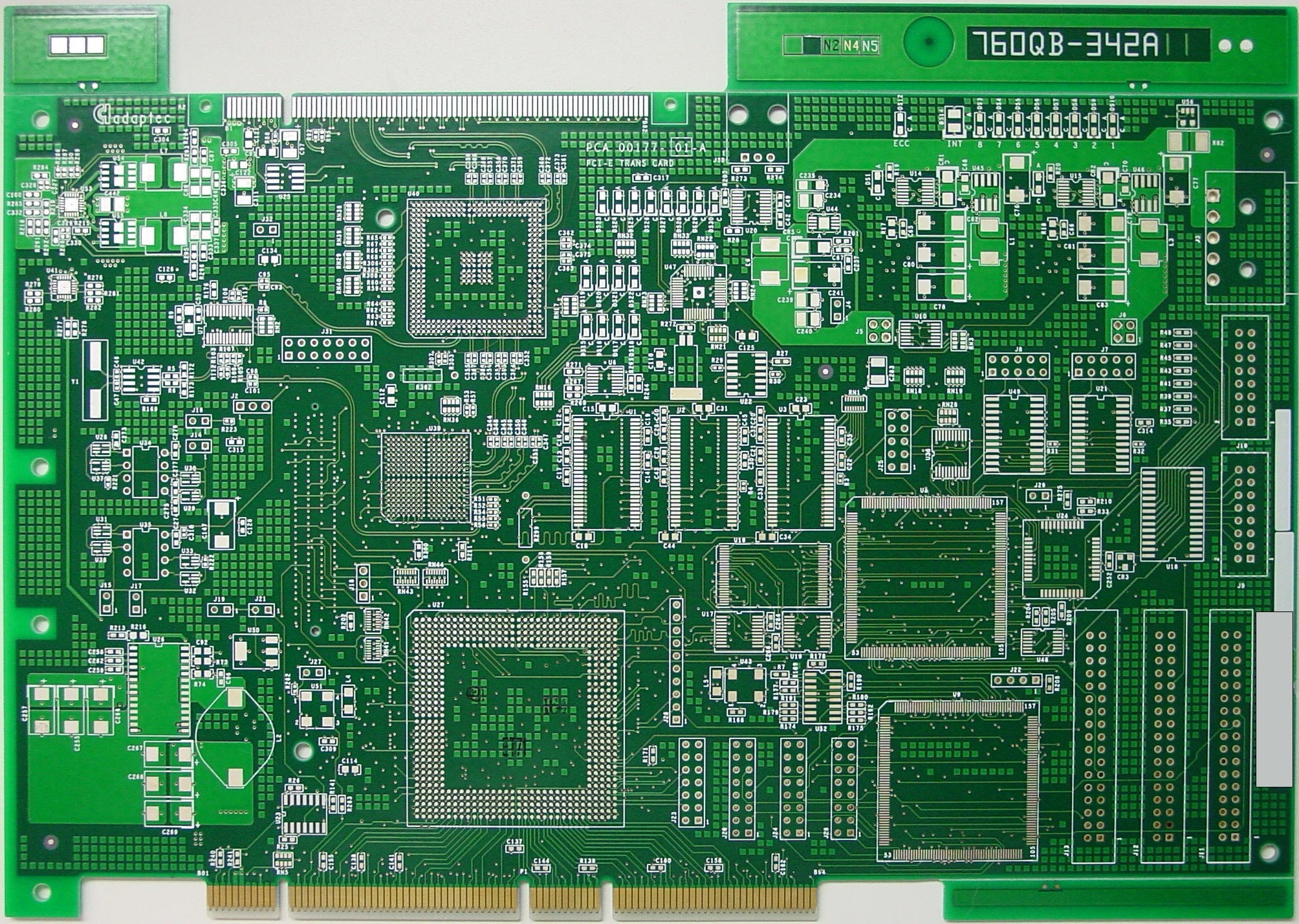

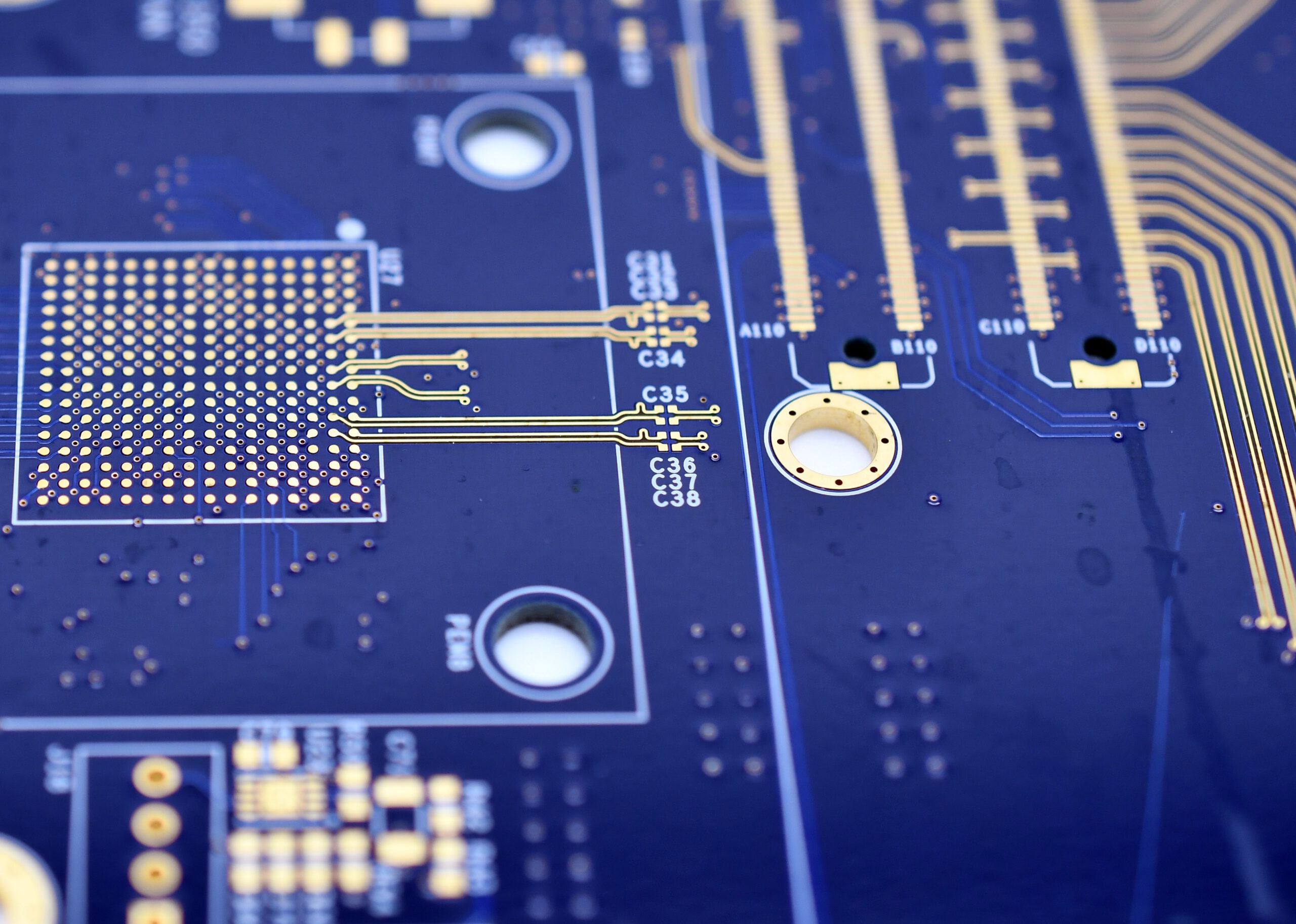

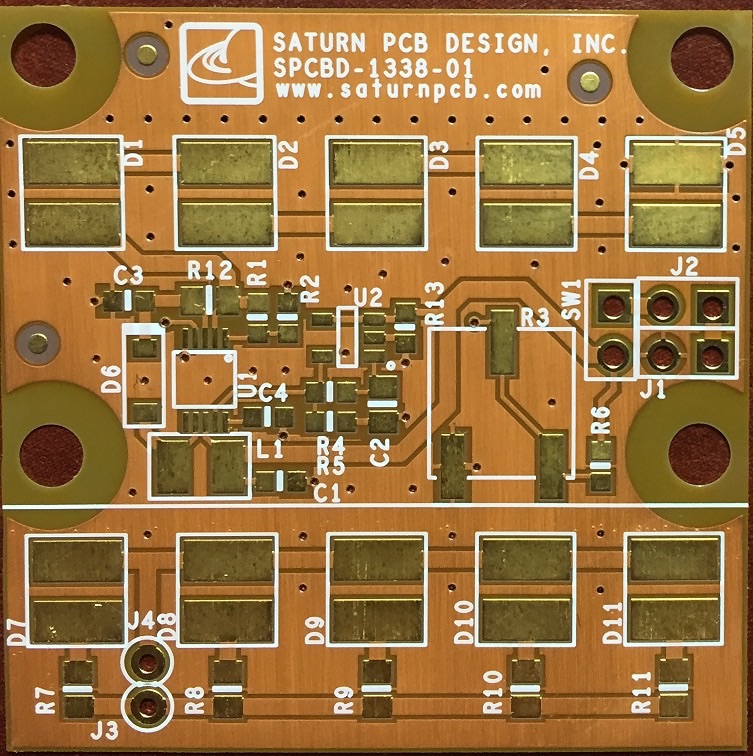

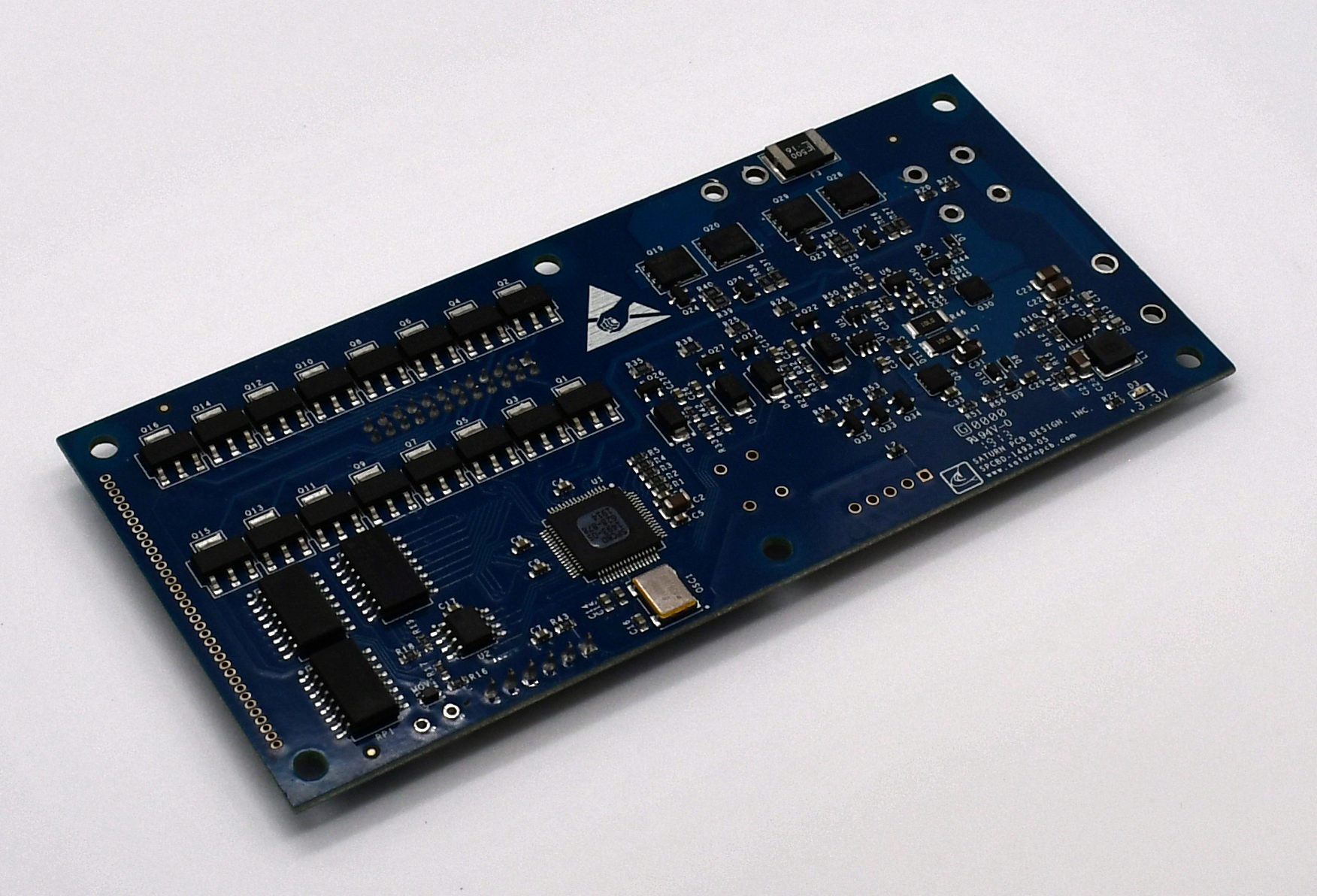

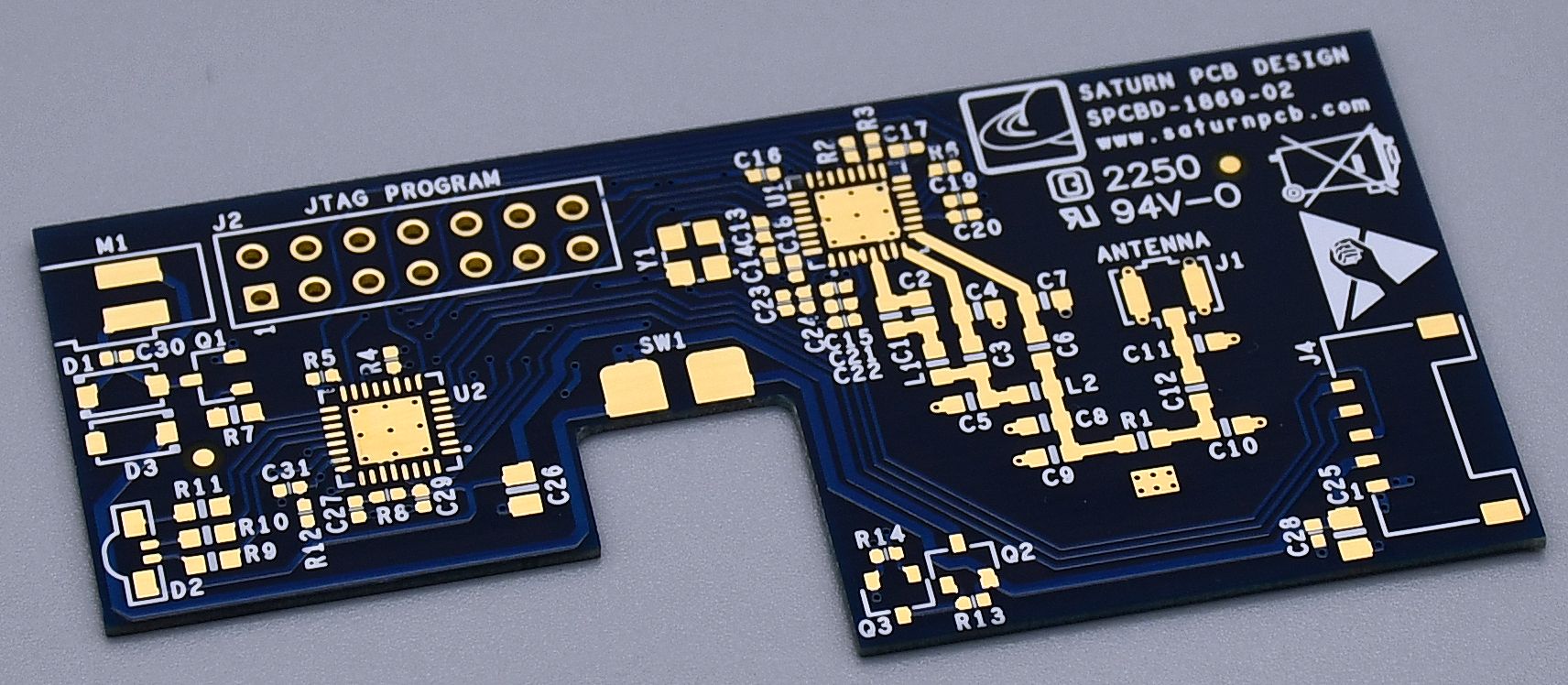

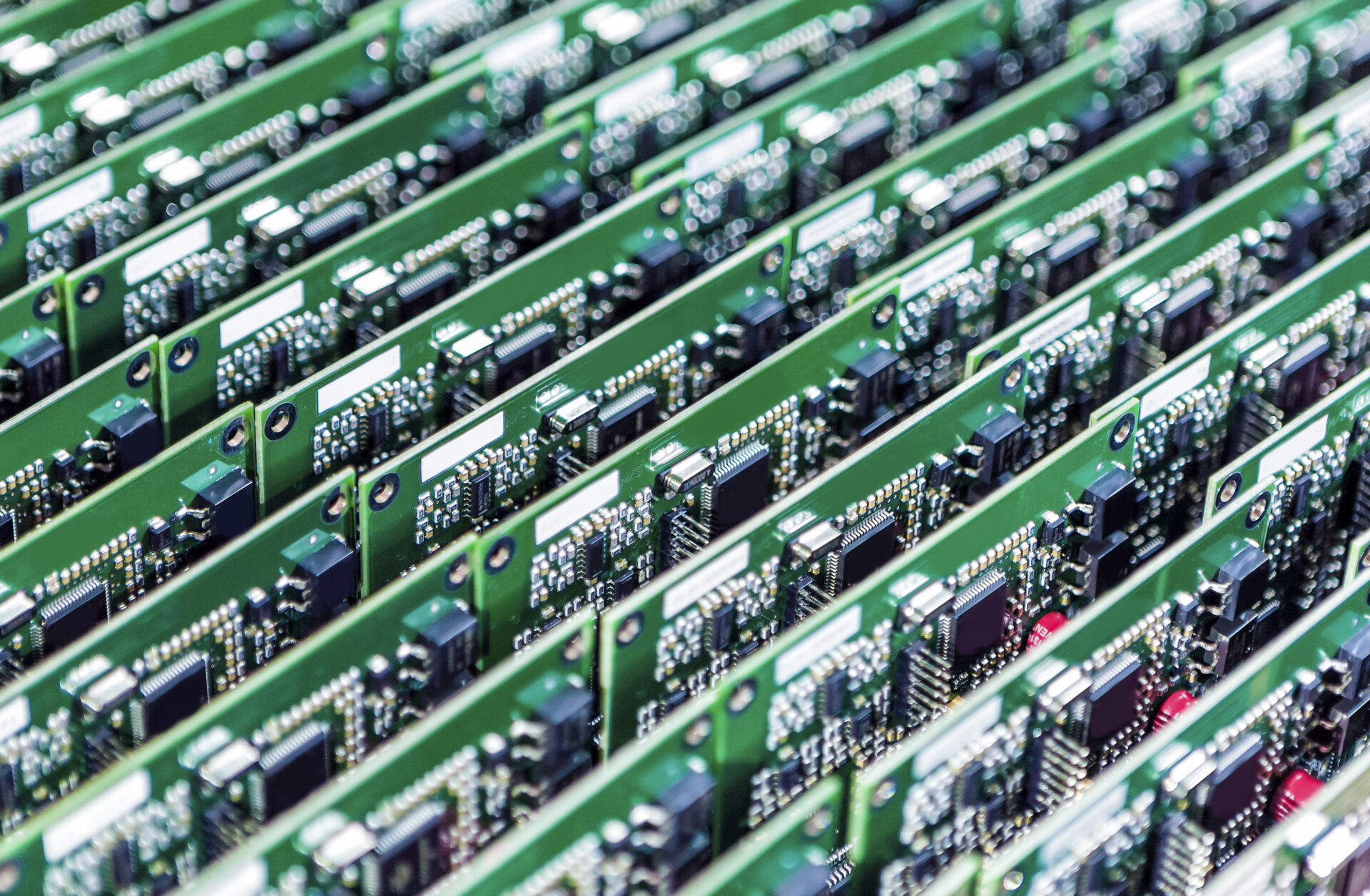

USA-Based PCB Manufacturing Services

Our PCB manufacturing services take your designed PCB (Gerber-formatted files) and turn it into a physical functioning circuit board. We specialize in translating your schematic and layout into a real product. PCB manufacturing includes: multilayer lamination, drilling and hole plating, electrical patterning, and surface finishing.

PCB Manufacturing Capabilities

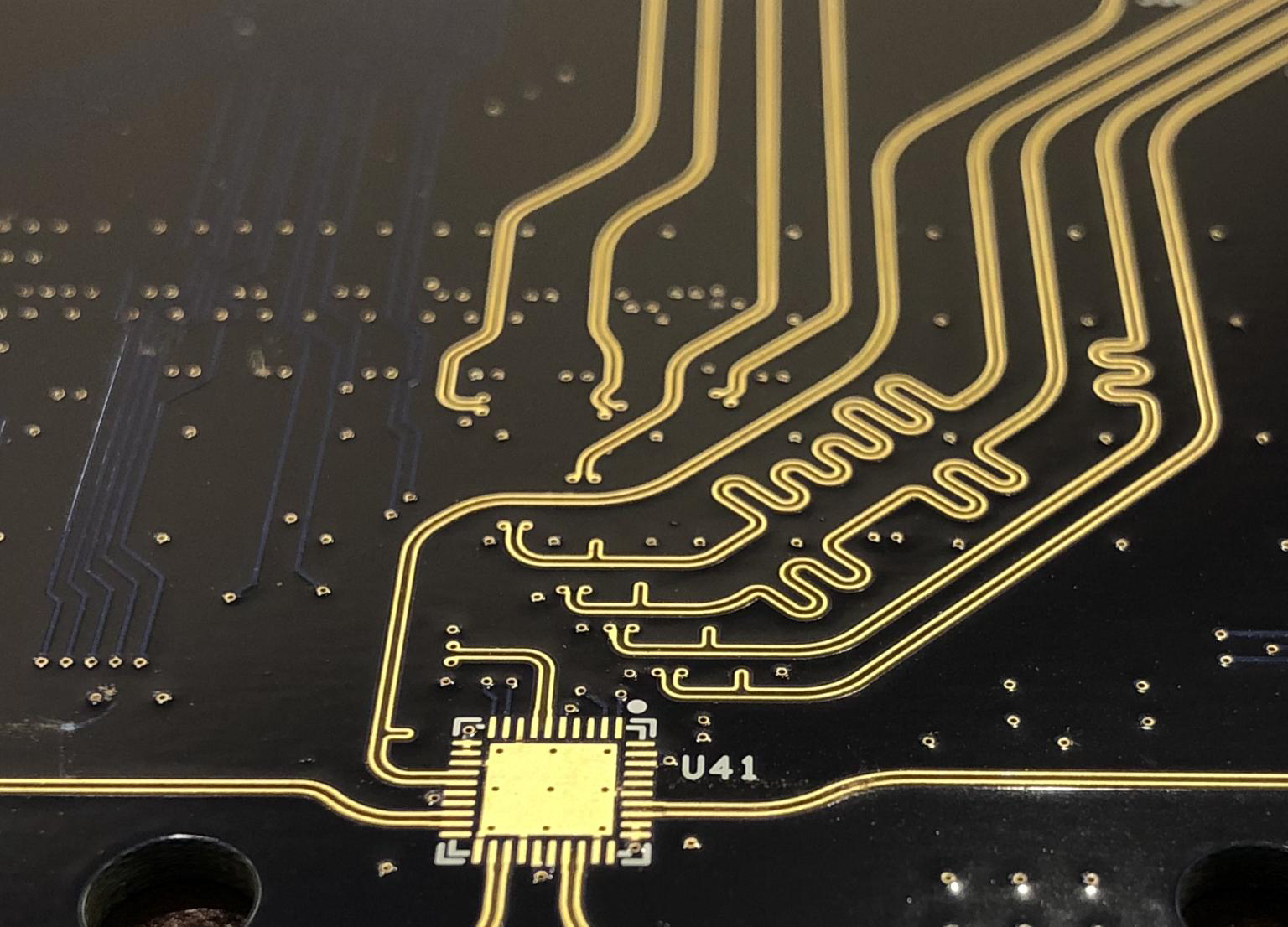

- Large format PCB’s

- 3/3mil technology

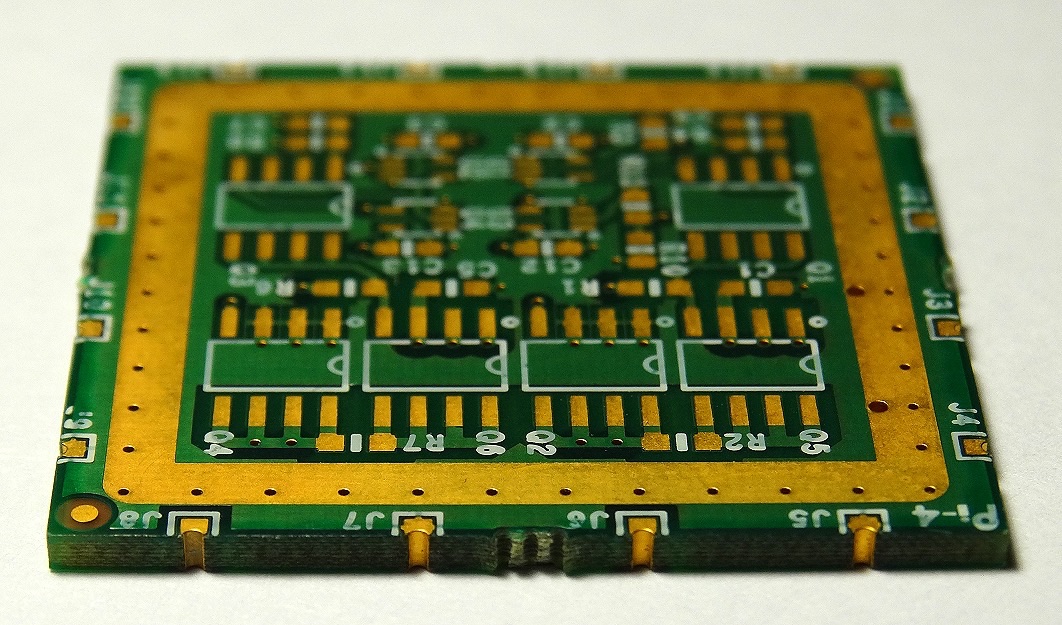

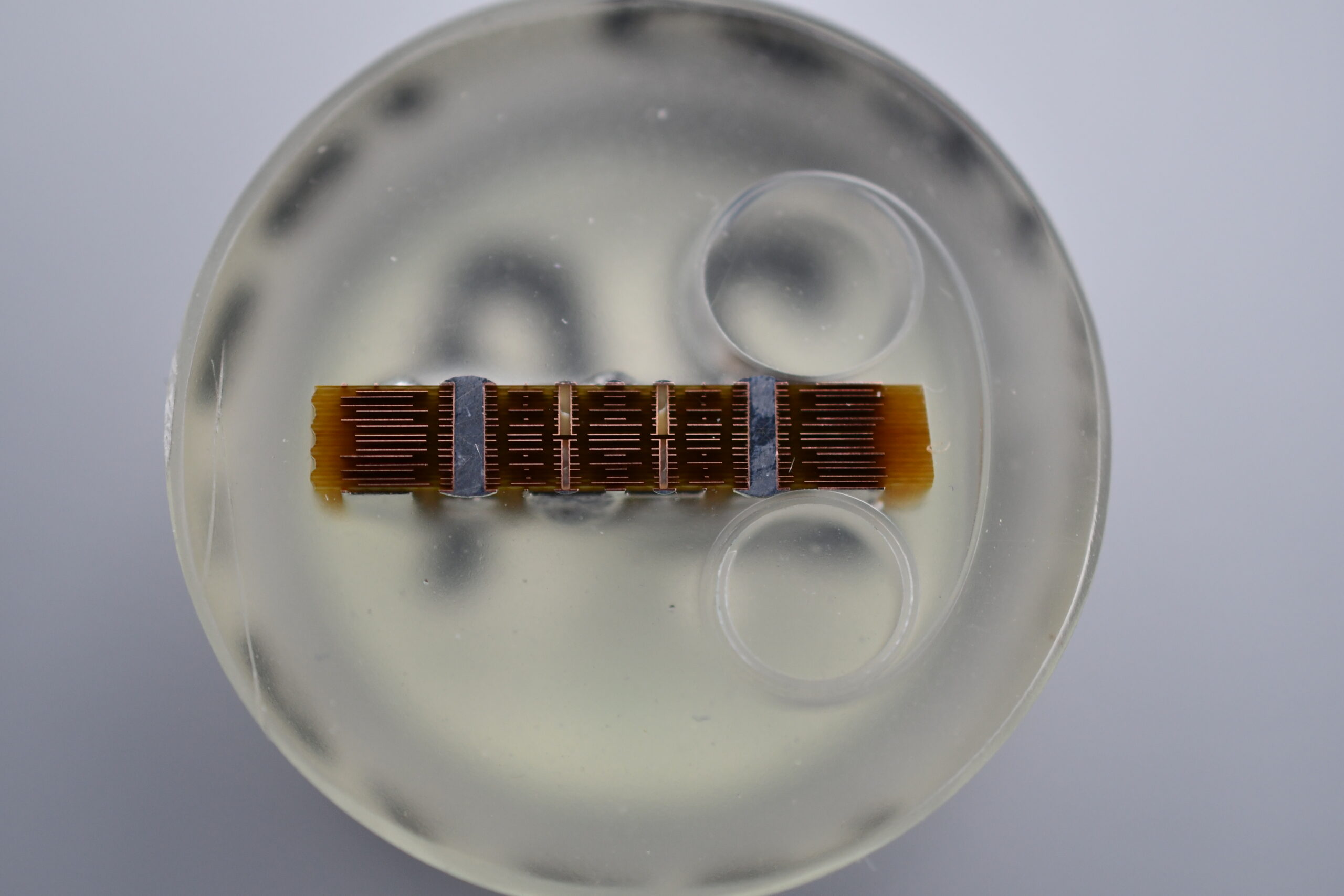

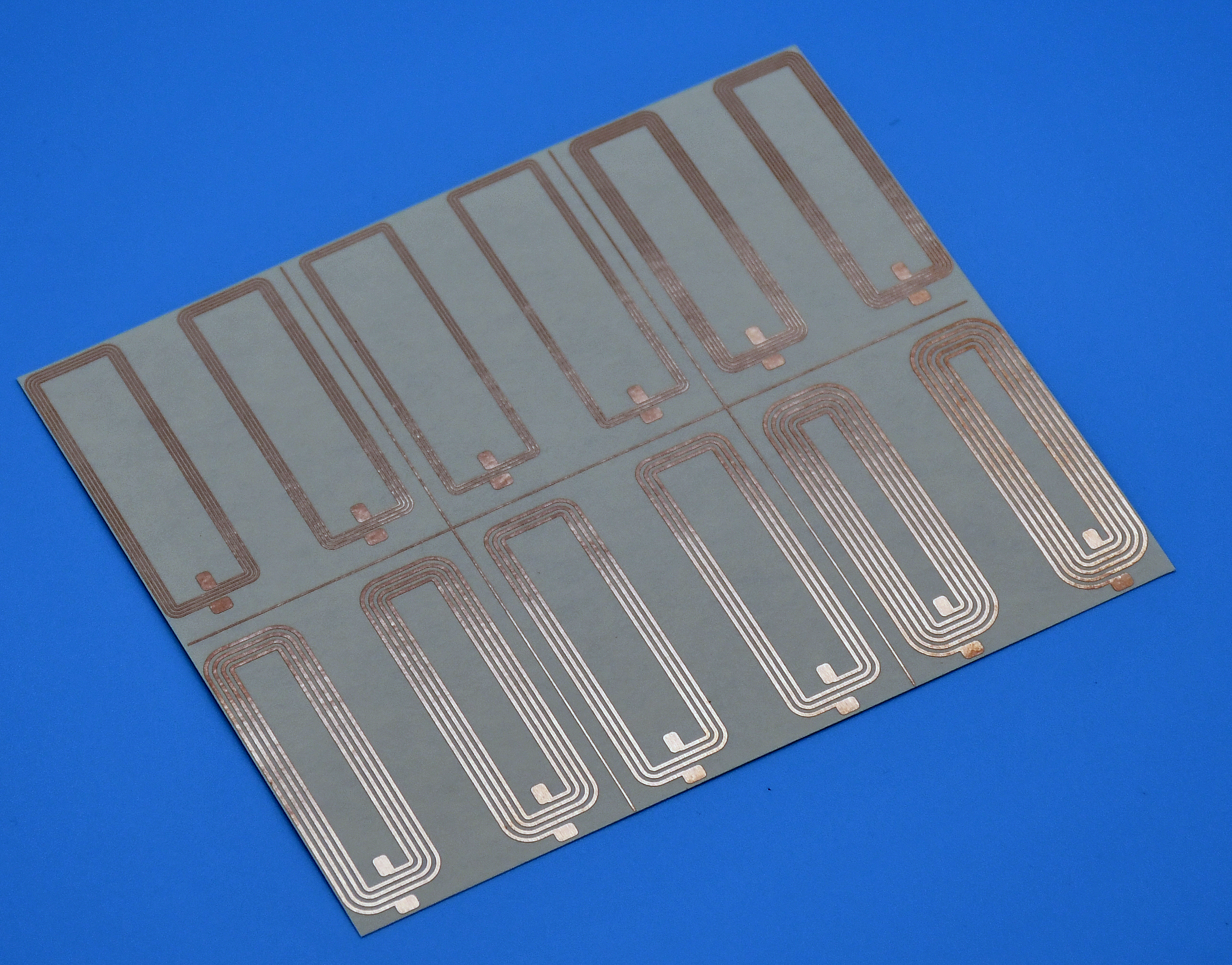

- Rigid, Rigid Flex, and FLex PCB’s

- Copper coin technology

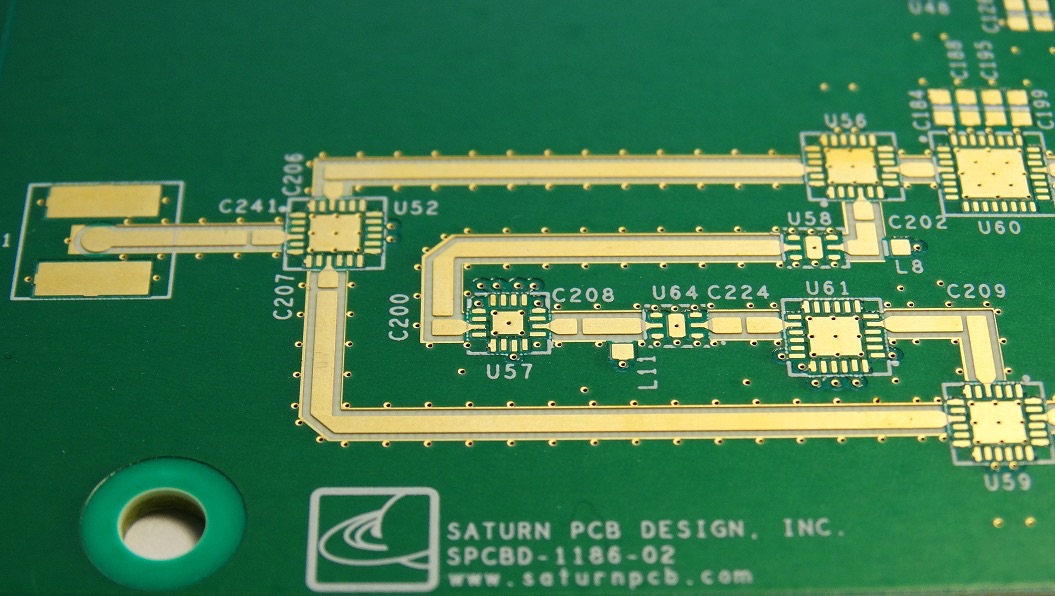

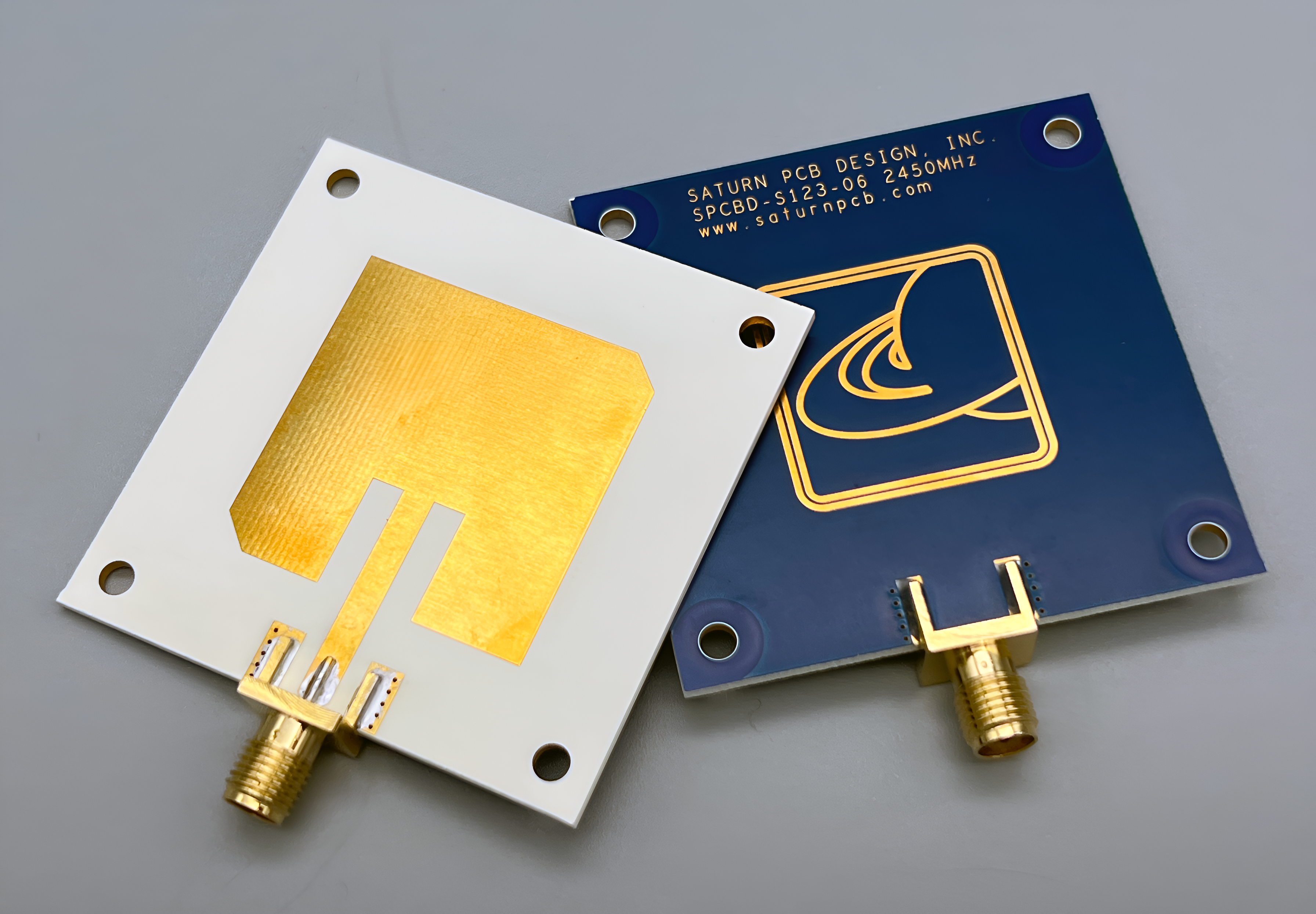

- Rogers RF substrates

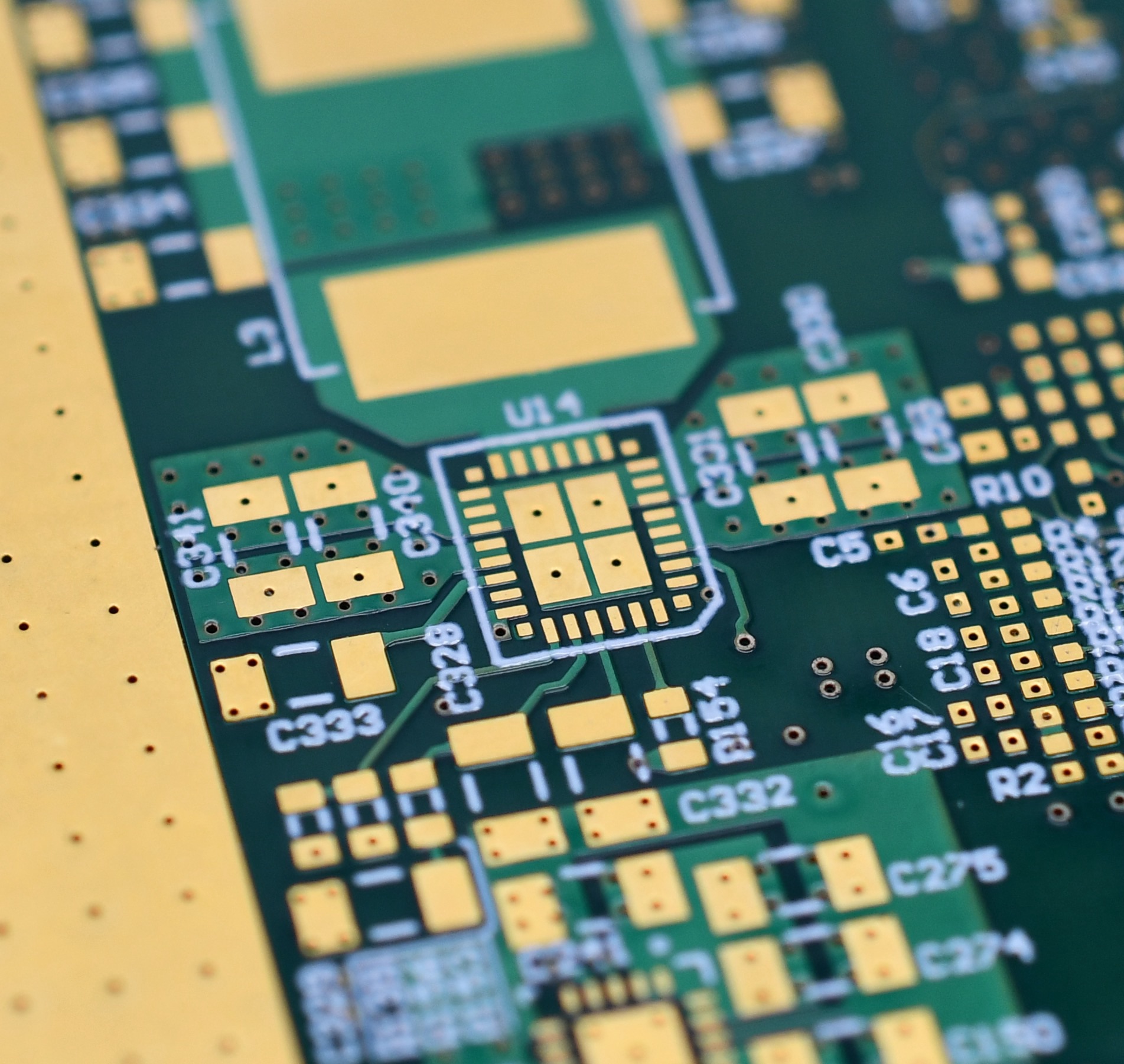

- High-Speed PCB substrates

- Laser microvias, blind vias, buried vias

- Bare board electrical testing

- PCB Impedance testing

- Class 2 & 3 quality

- RoHS Surface finishes

- Fast turnaround times

Quality Standards

- ANSI/ESD S20.20 2014

- AS9100:2004 and ISO9001:2008

- ISO 13485

- MIL-P-55110

- MIL-PRF-31032

- MIL-STD-45662

- IPC-600-A

- IPC-610-D

- J-STD-001

- IPC-CID

Substrates

- FR-4, High Temp

- Rogers 3000 Series

- Rogers 4000 Series

- Rogers 5000 Series

- Teflon

- Arlon

- Taconic

- Polyamide

- Aluminum

- TMM

- Nelco

- Kappa 438

Company Attributes

- Turnkey electronic engineering solutions that cover your project from concept to production

- Military, aerospace, medical, automotive and commercial applications

- Highly knowledgeable team of electronic engineers and PCB designers

- Experts in RF PCB Design, high speed digital PCB design and microwave electronic design

- Member of IPC designer’s council with PCB design certification

- Solid PCB manufacturing knowledge for superior designs

- Great communication with customers and comprehensive online design reviews

- Exceptional turnaround time on projects to help meet customer deadlines

- Complete confidentiality of your projects and IP

- Competitive prices on of our all services

- Worldwide customer base

Standard Capabilities

This is a list of our standard capabilities not our maximum capabilities. If your design needs anything outside of these specifications, please call or email us.

Materials and process per military and IPC spec. UL approved.

- Materials

- FR-4

- 370HR

- FR406

- FR408

- Nelco Buried Capacitance

- Polyimide

- Teflon

- Rogers

- Taconic

- Arlon

- Hybrid FR-4 / Rogers

- Layer Count

1 to 50 Layers

- Minimum line spacing

0.003″

- Material Thickness

0.002″ to 0.300″

- Minimum Annular Ring

0.005″

- Minimum drilled hole size

0.008″

- Maximum board size

35″ x 46″

- Maximum Copper Thickness

5oz.

- Solder Mask

SMOBC, LPI or Dry Film

- Finish Plating

- HASL

- Lead Free HASL

- Immersion Silver

- ENIG

- ENEPIG

- Matte Tin Plate

- Soft / Hard Gold for Tabs and SMT

- Selective Gold

- Palladium

- Silkscreen Colors

- White

- Yellow

- Black

- Solder Mask Colors

- Green

- Blue

- Red

- Black

- Clear

- Panelization

- Routing

- V-Groove

- Other Services

- Laser Vias

- Tented Vias

- Plated Slots

- Edge Plating

- Controlled Dielectrics

- Conductive Filled Vias

- Blind/Buried Vias

- ITAR